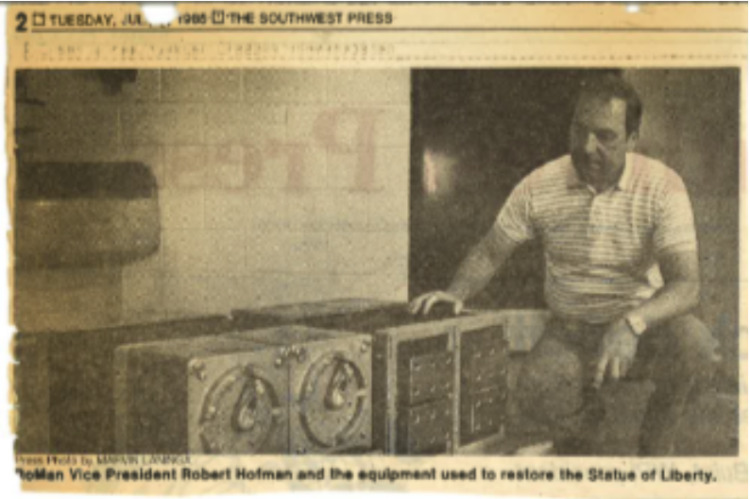

RoMan Manufacturing helps restore the Statue of Liberty!

In 1984, work was begun to restore the Statue of Liberty. At the time of the restoration, she was approaching her 100th birthday and her age was beginning to show. Of particular issue was the integrity of the iron armature used to hold the copper plates that made up Lady Liberty’s skin. Due to lack of regular maintenance; the marine environment; and a metallurgical reaction between the iron and copper; much of the iron was deteriorated. And although a number of the bars were replaced in 1938, by 1980, two-thirds of the bars were badly corroded, while all had some corrosion. After much discussion and research by the restoration team, a decision was made to replace the 1800 iron bars with

stainless steel.

In 1985, RoMan was approached by a New York company, Nab-Fiebiger who had been contracted to handle this part of the restoration project. They were working with Lors Machinery., a machine builder in New Jersey.

RoMan was contracted to develop and manufacture two transformers to treat the stainless steel bands used to anchor the 200,000 pounds of copper skin. The restoration was completed and the Statue of Liberty was re-dedicated on July 4th, 1986 during the centennial celebration.

Transformer Repair Services

Click below to request a Return Material Authorization (RMA) #.

Request A Quote

Requesting a quote is easy. Just provide the necessary information.